![]()

Technological innovation

▎ Application of BIM Technology

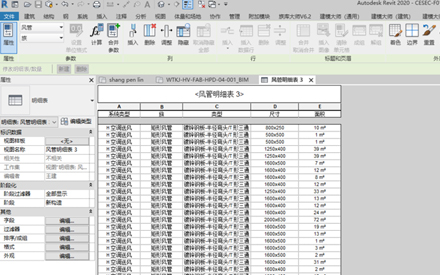

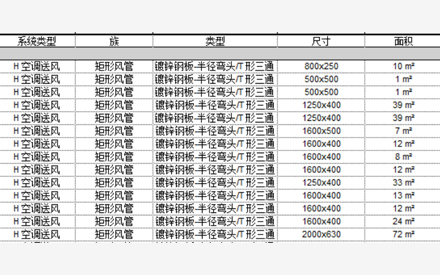

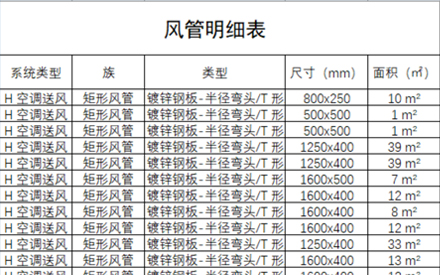

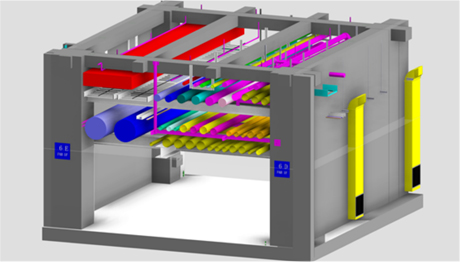

The company utilizes BIM technology to serve the entire project lifecycle, enhancing construction efficiency and quality. In the early and middle stages, BIM technology is used for comprehensive clash detection of pipelines to guide construction, 4D progress simulation, coordination of subcontractors and parallel construction processes, as well as material quantity takeoff and 5D construction management, reducing rework and improving construction quality. In the later stages, BIM technology is used to build a 3D operation and maintenance platform for users, improving maintenance management efficiency and bringing significant value to customers.

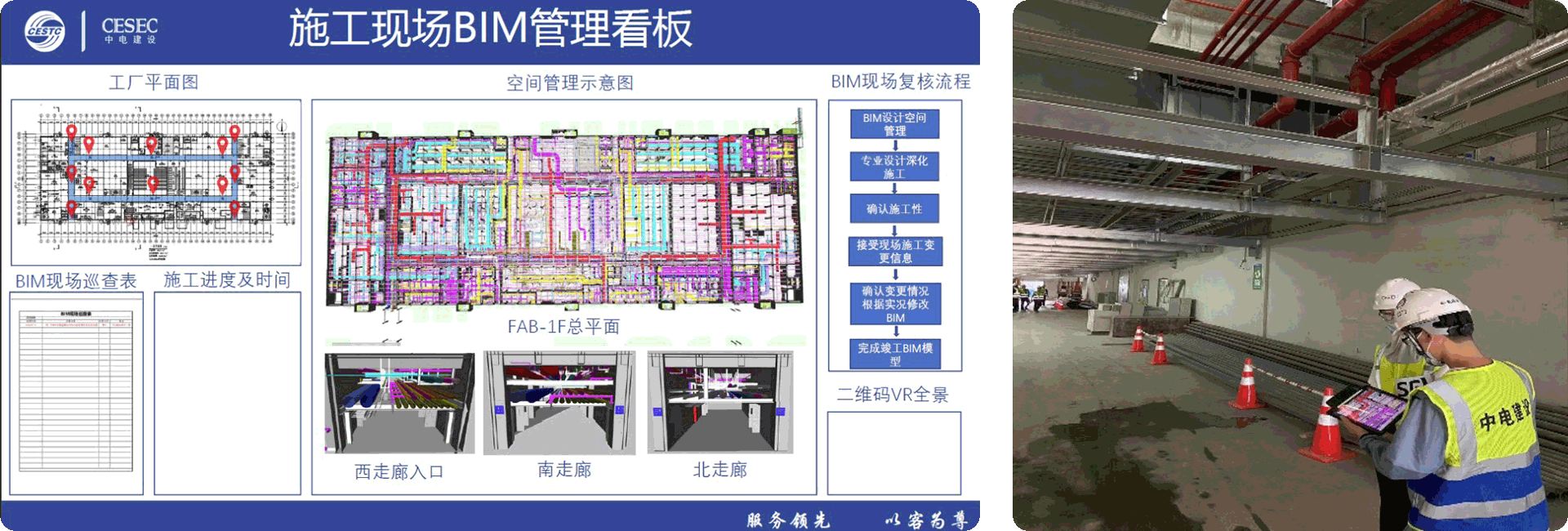

▎ Utilize On-Site Dashboard for Guiding Construction Based on BIM Models

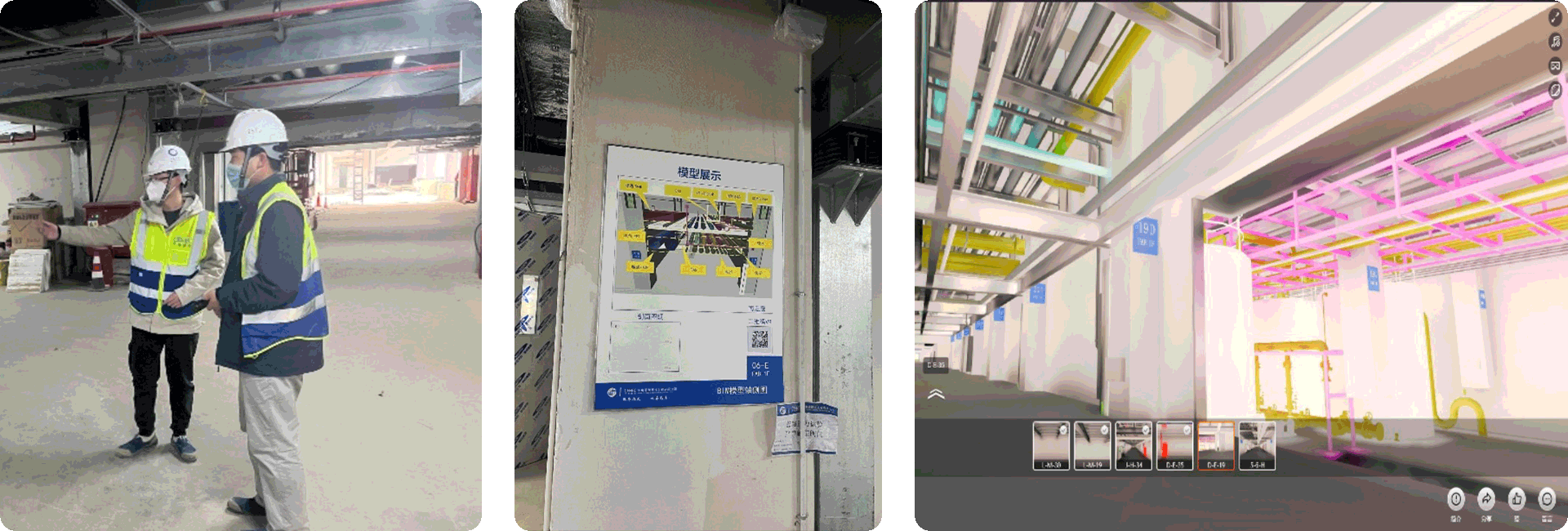

Guide On-Site Construction with Lightweight Models

Implement lightweight models for web and mobile display, bring the model to the site for construction guidance, and utilize real-time comparison for prompt feedback on site discrepancies and timely adjustments.

Establish Model Dashboard in Key Areas

Set up model dashboard in key and complex pipeline areas, and scan the QR code to access and review construction progress plans, pipeline three-dimensional cross-sections, and construction procedures for the area, facilitating on-site guidance

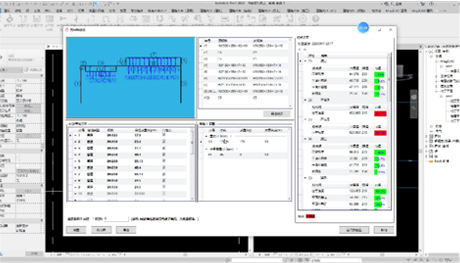

▎ BIM-4D progress simulation, coordinate the construction process of each subcontract and parallel package

▎ BIM-5D Progress Simulation for Coordinating Construction Sequences among Various Subcontractors and Parallel Packages

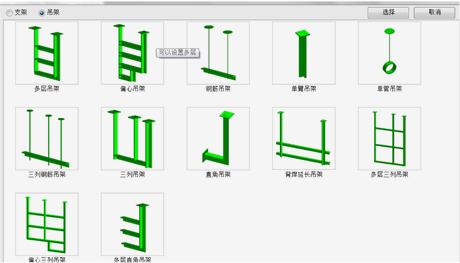

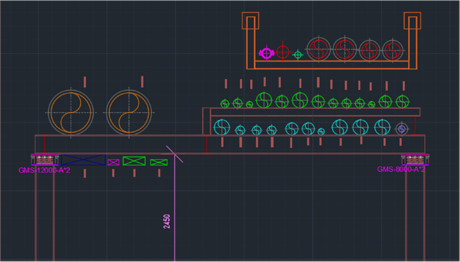

▎ Extensively Utilize Integrated Support Hangers to Save Materials, Enhance Aesthetics, and Reduce Expansion Bolts in Floor Slabs

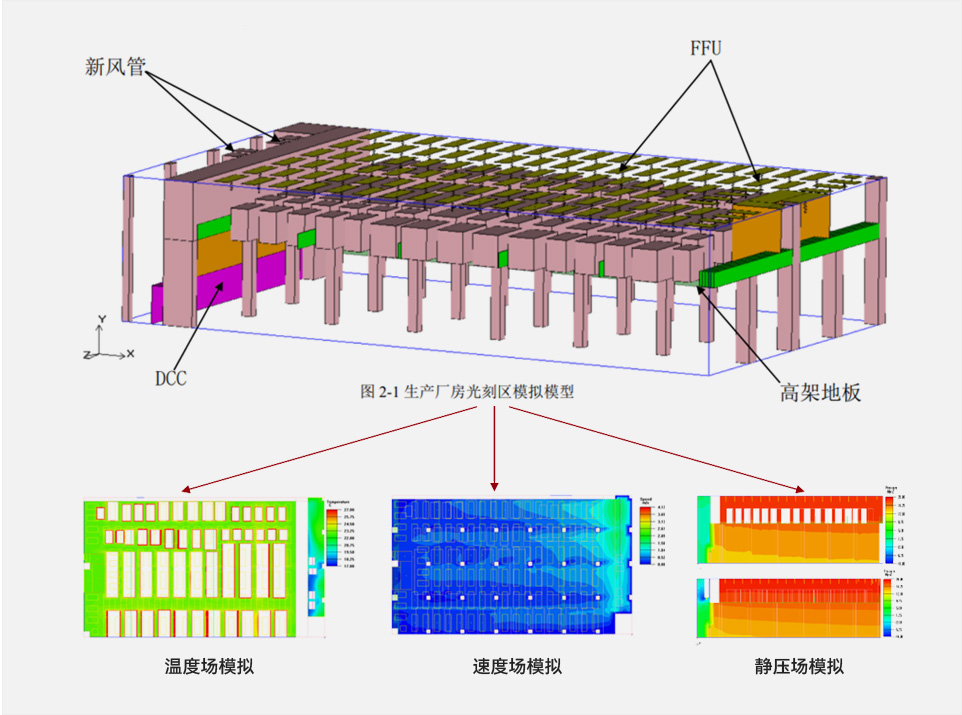

▎ CFD+BIM: Simulation of Airflow Organization in the Cleanroom Lithography Area to Ensure Stable Process Environment

BIM Building Model Export

Export drawings and model information, transmitting them through collaborative design platforms to interface with computational software for airflow simulation, and finally export model files in STL format.

Unified Design and Simulation Model

Omit the steps of rebuilding the calculation model during CFD calculations, ensuring the uniformity between simulation calculation models and actual designs, and guaranteeing accuracy.

CFD Airflow Organization Simulation

Utilize simulation software to optimize the positioning of supply and return air vents, as well as FFUs in the purification HVAC system, and conduct simulations of temperature distribution, velocity distribution, and static pressure distribution to ensure rational airflow organization and energy efficiency.

BIM Building Model Export

Export drawings and model information, transmitting them through collaborative design platforms to interface with computational software for airflow simulation, and finally export model files in STL format.

Unified Design and Simulation Model

Omit the steps of rebuilding the calculation model during CFD calculations, ensuring the uniformity between simulation calculation models and actual designs, and guaranteeing accuracy.

CFD Airflow Organization Simulation

Utilize simulation software to optimize the positioning of supply and return air vents, as well as FFUs in the purification HVAC system, and conduct simulations of temperature distribution, velocity distribution, and static pressure distribution to ensure rational airflow organization and energy efficiency.